How is a monofill different from a landfill?

Unlike traditional landfills which can co-mingle household and industrial wastes, a monofill is a carefully engineered site designed to house only one type of waste. The Hoover Mason Recycling monofill accepts only the nonhazardous salt slag and baghouse dust by-product created by the aluminum recycling process.

How Does the Aluminum Recycling Process Work?

There are two sources of aluminum recycled by SSC and TAP. The first is scrap which can consist of anything from used beverage cans to obsolete airplane and car parts. The second source is dross which is a by-product that forms when molten aluminum comes into contact with air or other impurities in a reverberatory furnace. Dross can contain 10-80% aluminum and is recycled by SSC and TAP to recover the available metal. The scrap or dross is mixed in a rotary furnace with additives such as salt and potash and is heated by natural gas/oxygen enriched burners until the molten aluminum is ready to be extracted. The material left over in the rotary furnace after the molten aluminum is poured is called salt slag.

What Is Salt Slag and Baghouse Dust?

Salt slag and baghouse dust are by-products created during the SSC/TAP aluminum recycling process. Salt slag is a solid residue that remains in a rotary furnace after the aluminum is extracted. Salt slag is nonhazardous and is primarily composed of aluminum oxide, salt and potash. Baghouse dust is also a nonhazardous by-product of the melt process that is collected by add-on emission control devices located throughout the SSC and TAP aluminum recycling facilities.

How Was the Site for Hoover Mason Recycling Chosen?

SSC and TAP own 170 acres of previously strip mined land adjacent to the TAP recycling facility. The site was selected after geological investigations of several locations determined that this site displayed favorable characteristics for a monofill application. Only 39 acres of the land are set aside for waste disposal while the rest is being utilized for buffer, facilities, storm water control ditches, leachate (waste water) collection and soil borrow.

How Is the Site Constructed?

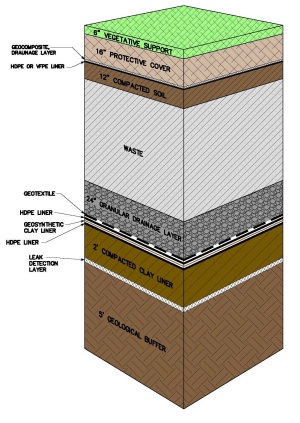

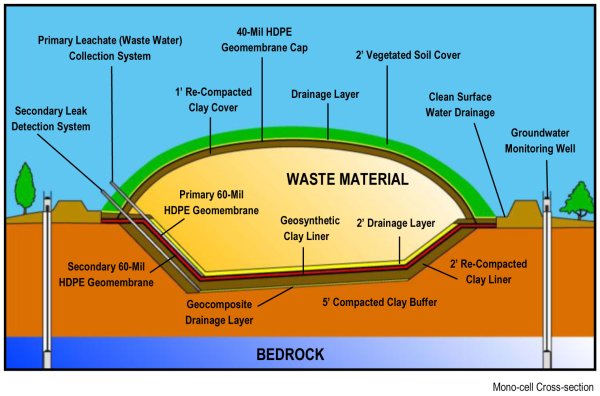

Hoover Mason Recycling exceeds state and federal mandates applying to similar Class II industrial landfills. The site is divided into phases called mono-cells, and each mono-cell is carefully engineered with layers of barriers and drainage systems. In the event any moisture comes into contact with the waste material, it is captured in the drainage layer then removed through a sealed collection system and stored onsite in a containment tank. Once the tank is near capacity, it is shipped to a certified waste water treatment facility.

How Is the Site Managed?

Hoover Mason Recycling is managed by an internationally certified waste professional who maintains certification through required continuing education. The manager ensures that all federal/state regulations are followed, monitors all daily activities and oversees the construction of each mono-cell. Also to ensure the proper management of the salt slag and baghouse dust, the material is cooled before disposal, is placed only in dry weather, is covered daily with at least six inches of compacted clay and no more than a 60’ x 60’ area is exposed at one time.